According to the requirements of one industrial sewing machine (ISM) manufacture, a kind of digital servo system for ISM has been designed in this paper. First of all, SVPWM has been analyzed in driving Permanent Magnet Synchronous Machine (PMSM) carefully. Afterwards, a reliable method adopted for both speed and position measurement without photoelectric encoder has been presented. Then, considering about the speed regulating for the servo system, nonlinear PI control algorithm with the control strategy of single closed loop has been proposed. And meanwhile, a ‘Five Steps’ algorithm for needle location of the system has been discussed in detail. At last, with both simulation and test results, the validity and veracity of the control strategies for motor driving, motor speed regulating and needle location of ISM can be proved effectively.

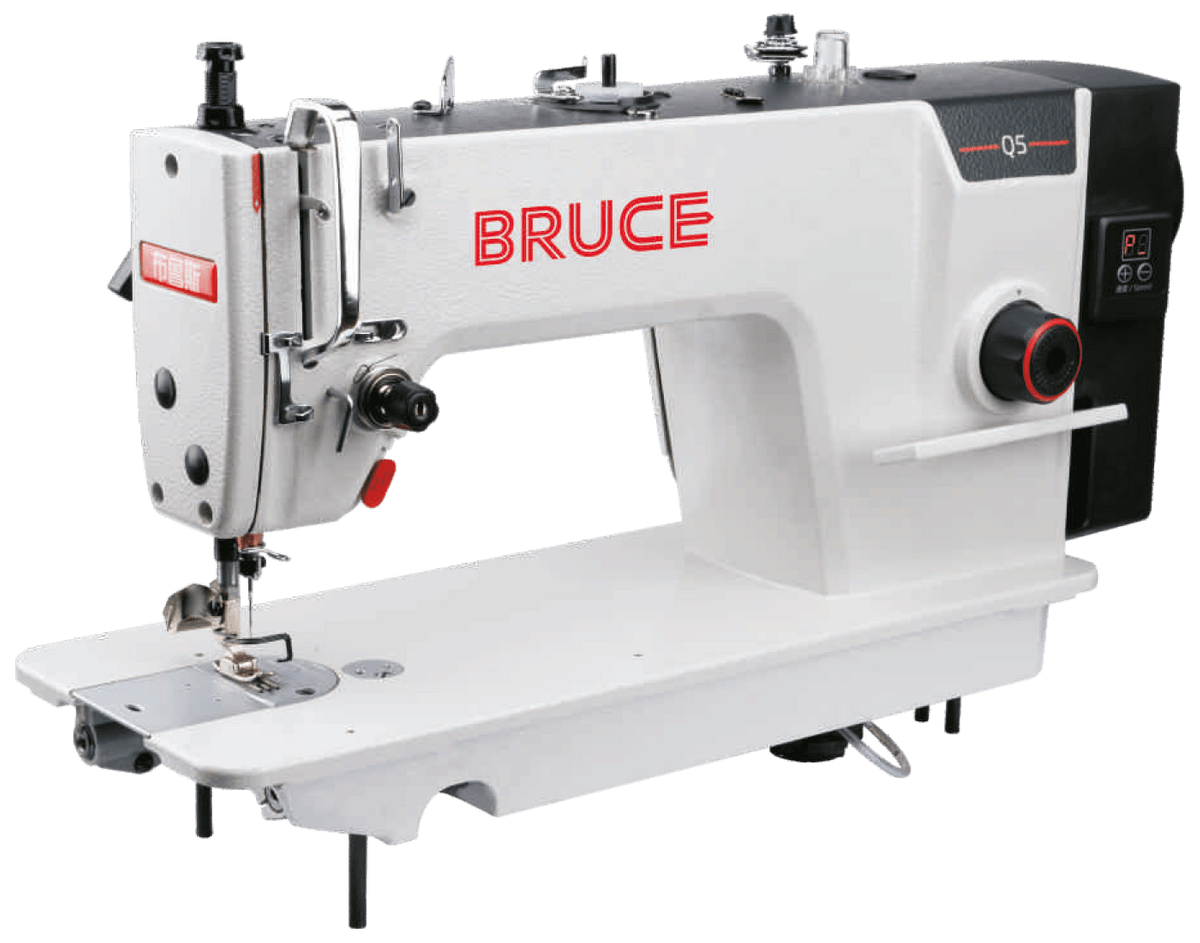

With the intense globalization of the world economy and the rapid transferring of the global manufacturing of industrial sewing machine (ISM), China has become the largest base for ISM producing since 2001 when the country entered the World Trade Organization (WTO). And meanwhile, accompanied with the endless development of digital and computer technique, power and electron technology and control theories, the research on ISM have been focused on higher precision, more energy-saving, lower cost, higher speed, multiple-function and more intelligence [1]. As the result, it is significant to develop such a kind of digital ISM servo system based on computer control with high performance. With the merits of low cost, small mechanical noisy, long continual working time, convenient maintenance, wide timing scope of the running belt and small speed wave, Brushless DC Motor (BLDCM) has been widely applied in ISM [2]. Ref. [3] and [4] designed an ISM servo system with BLDCM. However, it is difficult to deal with torque ripple, occurred especially when the motor running at low speed, which may aggravate the performance of the system seriously. Best merit sewing machine in velachery Ref. [5] and [6] presented some methods to suppress the torque ripple of BLDCM, but they are not suitable for ISM because of more complex construction, higher cost and less effectiveness. Currently, Permanent Magnet Synchronous Machine (PMSM) based servo systems has been attracted by more and more researchers, for which has several inherent advantages compared with other types of electric machinery, such as high power density, high power factor, high torque to current ratio, high efficiency, low inertia, rugged construction, easy for maintenance and so on [1], [4], [7]. Ref. [8] presented an ISM servo system designed by PMSM. In the system, a 1/360 type’s photoelectric encoder was used as the position sensor to measure the rotation speed and determine the rotor position, and SVPWM technique and nonlinear PI control algorithm were adopted in motor driving and motor speed regulating respectively. In accordance with the test report illustrated in the final chapter of Ref. [8], the effectiveness of the mentioned control method can be verified. Nevertheless, the cost of the whole system is still expensive due to the high level price of the photoelectric encoder. https://vssewingmachine.in/ With the purpose of both acquiring nice performance and reducing the cost of the system, this paper has studied and designed an ISM servo system based on PMSM without photoelectric encoder. In section II, we discusses some key important techniques about motor drive and motor speed control which include SVPWM, motor speed surveying, motor position determining, and control algorithm for speed regulation. A ‘Five Steps’ algorithm applied to needle location is presented in section III. Section IV exhibits the results of both system simulation and system test. Finally, the conclusions are given in the last section.